Why Plastic Injection Molding Is Vital for Accuracy and Durability

Why Plastic Injection Molding Is Vital for Accuracy and Durability

Blog Article

Trick Advantages of Using Plastic Injection Molding in Manufacturing

Plastic shot molding has actually become a pivotal technique in the manufacturing sector, offering a variety of benefits that substantially improve manufacturing procedures. Noteworthy benefits consist of impressive production performance, the capacity for elaborate styles, and a positive cost structure that attract businesses of all sizes. In addition, the flexibility of materials made use of in this technique adds to the durability and integrity of the end products. Understanding these crucial benefits can illuminate just how business can enhance their production strategies, yet the ramifications prolong much past first expense savings and efficiency metrics.

High Manufacturing Efficiency

Among one of the most considerable benefits of plastic shot molding is its high production effectiveness, which can lead to the rapid production of hundreds of identical parts within a short timeframe. This efficiency is mainly credited to the automated nature of the injection molding procedure. When the preliminary configuration and mold creation are completed, the production of components can be scaled up significantly without an equivalent boost in labor expenses or time.

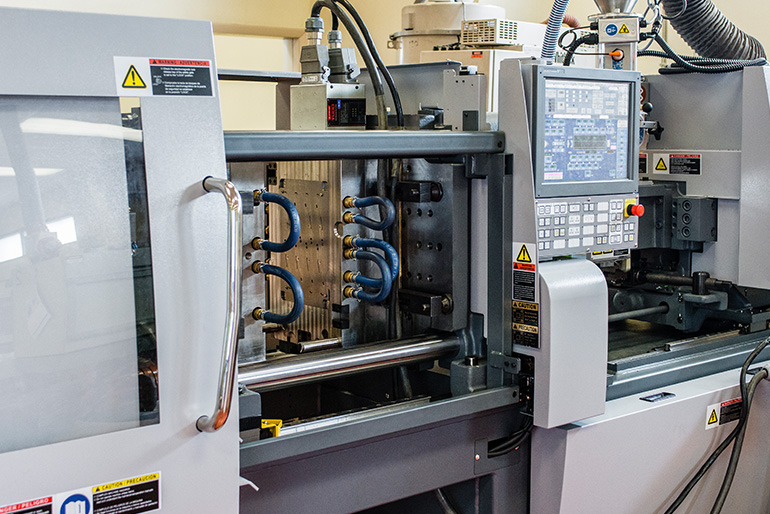

The procedure typically includes home heating plastic pellets till they thaw, injecting the molten material right into a precisely created mold, and enabling it to cool down and solidify - Plastic Injection Molding. This cycle can be finished in mere secs to mins, depending on the complexity and size of the part being created. As a result, manufacturers can accomplish high outcome prices, making plastic injection molding a perfect option for mass manufacturing

Additionally, the capacity to generate huge quantities consistently makes certain reduced device prices, making it a cost-efficient solution for services. This production performance not only satisfies market demands swiftly but additionally enhances the general competitiveness of suppliers in different markets. As a result, plastic injection molding remains a preferred technique for high-volume manufacturing applications.

Design Versatility

The abilities of plastic shot molding prolong beyond high manufacturing effectiveness to incorporate considerable style adaptability. This production procedure allows designers and engineers to develop complicated and elaborate forms that could be tough or impossible to accomplish with other techniques (Plastic Injection Molding). The capability to conveniently modify and adjust mold and mildew layouts means that suppliers can swiftly respond to altering market demands and introduce brand-new product styles without substantial retooling

In addition, plastic shot molding supports a variety of products, consisting of numerous thermoplastics and thermosetting polymers. This range allows the manufacturing of parts with unique buildings, such as enhanced toughness, light-weight qualities, or details thermal and electrical features. In addition, the procedure enables the assimilation of numerous features into a solitary component, minimizing the need for assembly and decreasing potential points of failing.

The accuracy of injection molding likewise guarantees that components are produced with tight tolerances, boosting fit and feature. The adaptability to generate small to huge sets effectively further highlights its flexibility, making it an optimal option for both prototyping and large manufacturing. In general, design flexibility is a foundation benefit of plastic shot molding, driving advancement in various industries.

Cost-Effectiveness

Cost-effectiveness attracts attention as a significant benefit of plastic injection molding in manufacturing. you can check here This process allows for the automation of top notch plastic parts at a reasonably inexpensive per device, particularly when compared to various other manufacturing methods. The performance of shot molding exists in its capability to generate complex shapes with very little waste, enhancing material use and reducing general expenses.

Furthermore, the site here rate of manufacturing is an essential consider cost-effectiveness. When the preliminary mold and mildew is developed, the time needed to produce each succeeding part is dramatically decreased, bring about enhanced outcome and faster turnaround times. This rapid manufacturing capability not just satisfies high-volume demands yet likewise lessens labor costs, as automated systems can manage much of the procedure.

Moreover, the toughness and durability of injection-molded items add to their cost-effectiveness with time. These components usually need less maintenance and substitute, resulting in reduced lifecycle prices for makers and end-users alike. In summary, the cost-effectiveness of plastic injection molding makes it an eye-catching option for companies seeking to boost their production performance while preserving product high quality.

Material Adaptability

Material flexibility is a trademark of plastic injection molding, allowing makers to select from a wide array of polymers that fulfill particular performance demands. This versatility enables the production of components customized to numerous applications, ranging from hop over to these guys vehicle parts to customer products.

Frequently used products consist of acrylonitrile butadiene styrene (ABDOMINAL MUSCLE), polycarbonate (PC), and polypropylene (PP), each offering special properties such as influence resistance, warm resistance, and chemical security. Manufacturers can pick products based upon features like stamina, weight, and thermal stability, making certain completion product satisfies visual and practical requirements.

Furthermore, the ability to incorporate different polymers via co-injection methods further enhances material versatility. This permits the creation of multi-layered parts with distinct qualities, such as soft-touch surfaces incorporated with rigid structural components.

Additionally, improvements in naturally degradable and recycled materials are increasing the alternatives available, aligning with sustainability goals in manufacturing. In general, the diverse product options in plastic shot molding encourage suppliers to innovate and maximize their items, promoting the growth of very specialized and competitively helpful remedies.

Improved Product Toughness

Boosted product longevity is among the considerable advantages offered by plastic shot molding, as the production process permits for exact control over product properties and element design. This precision ensures that the end products exhibit enhanced mechanical toughness and resilience, which are vital consider a series of applications, from durable goods to commercial elements.

Moreover, the detailed geometries possible via injection molding enable the development of components that can stand up to stress and strain much better than typical manufacturing methods. The consistent wall surface thickness and decreased product waste also contribute to the general honesty of the product, decreasing the chances of failing during its lifecycle.

Conclusion

In verdict, plastic injection molding offers significant advantages in production, consisting of high production effectiveness, design flexibility, and cost-effectiveness. The approach's ability to rapidly produce large quantities of similar components while lessening labor and product waste is paramount. The flexibility in material choice adds to enhanced product resilience and lower lifecycle prices. These factors jointly establish plastic injection molding as an ideal service for automation applications, resolving the dynamic requirements of modern-day production settings.

Plastic injection molding has actually arised as a pivotal method in the production field, providing a variety of advantages that considerably boost production processes.One of the most considerable benefits of plastic shot molding is its high production effectiveness, which can result in the fast production of thousands of the same components within a brief duration. Plastic Injection Molding.The capabilities of plastic injection molding expand beyond high production effectiveness to incorporate considerable layout versatility.In conclusion, plastic injection molding presents substantial benefits in production, consisting of high production effectiveness, style flexibility, and cost-effectiveness. These factors jointly establish plastic injection molding as an ideal remedy for mass manufacturing applications, dealing with the dynamic demands of modern manufacturing atmospheres

Report this page